WHEEL ASSEMBLY

AND LOGISTICS

Our services also include:

Warehouse for parts

Building and destressing

Certification

Seal of origin

Shipment

Workshop

Among our facilities there’s a well equipped workshop, to provide our customers with a technical service on bicycles that goes well beyond the wheels. In fact, we regularly build, for our customers, complete bicycles for trade shows or events.

Lathe

In a good workshop a lathe is a must, to make bushings, spacers, washers or anything esle needed to meet the urgent needs of our customers.

Spoke cutting and threading machine

A classic among wheelbuilder’s tools, cuts the spokes to the desired length, and at the same time rolls the thread. It may look like and old fashion tool, but truth is we use it to build prototype wheels with unusual spoke lenghts.

Warehouse

We keep a substantial stock of the most popular spokes and nipples, to be able to make prototypes or small production runs, without having to wait the producer’s lead-times. Naturally, we also offer warehouse logistics for the parts that our customers procure and ship to us, for the wheels we build for them.

Over the years we developed a good partnership with the belgian company Sapim, whose spokes constitue our biggest inventory.

Assembly equipment

The first phase is lacing, where the hub, spokes, nipples and rim are joined together in a wheel with minimal tensions.

Tool for tensiometers calibration

The tensiometers used in wheelbuilding must be regularly recalibrated and also calibrated for each different spoke used, for them to provide precise values. We use a very precise digital instrument to monitor and calibrate our tensiometers on a daily basis.

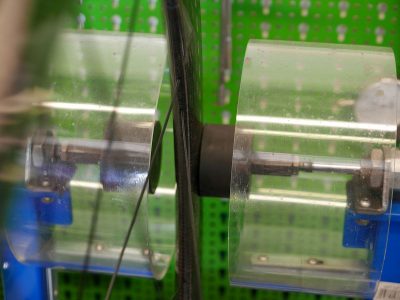

Hub pushing piston

In addition or instead of rim-pushing-pistons, we have a machine that destresses the wheel as a whole. It is an operation that is useful with certain wheel configurations.

Tensioning

the tension progressively applied to the spokes is continuously monitored with the appropriate tools, which are calibrated daily on the specific spoke used (model and length).

Rim pushing pistons

Destressing, a fundamental operation for the creation of wheels that remain centered for a long time and to maximize the life of the spokes, is repeated several times in the truing and tensioning phase, with axial piston pushing on the rim, calibrated to customer specifications.

Dish control

The wheel dish must be continuously checked during the building phases.

Threadlocker application

According ased on the customer’s needs and the particular configuration of the wheel, we can apply specific threadlocking to the nipple-spoke interface, to guarantee a stable and long-lasting coupling where necessary.

Threadlocker stabilizer

We have motorized rollers to keep the wheel spinning during the initial solidification phase of the threadlocker.